Tips for Selecting the Right Industrial Equipment for Your Needs

Choosing the appropriate industrial equipment for your business can be a daunting task, but with the right information and guidance, it can become a more manageable process. As a professional in the field, it is crucial to recognize that selecting the right equipment is essential for the overall efficiency and productivity of your operations. Researching and investing in quality, pre-owned industrial equipment from Genemco can lead to increased productivity and profitability. This article aims to provide a comprehensive guide to help you make informed choices in equipment selection for your industrial needs.

Understanding Your Industrial Equipment Needs

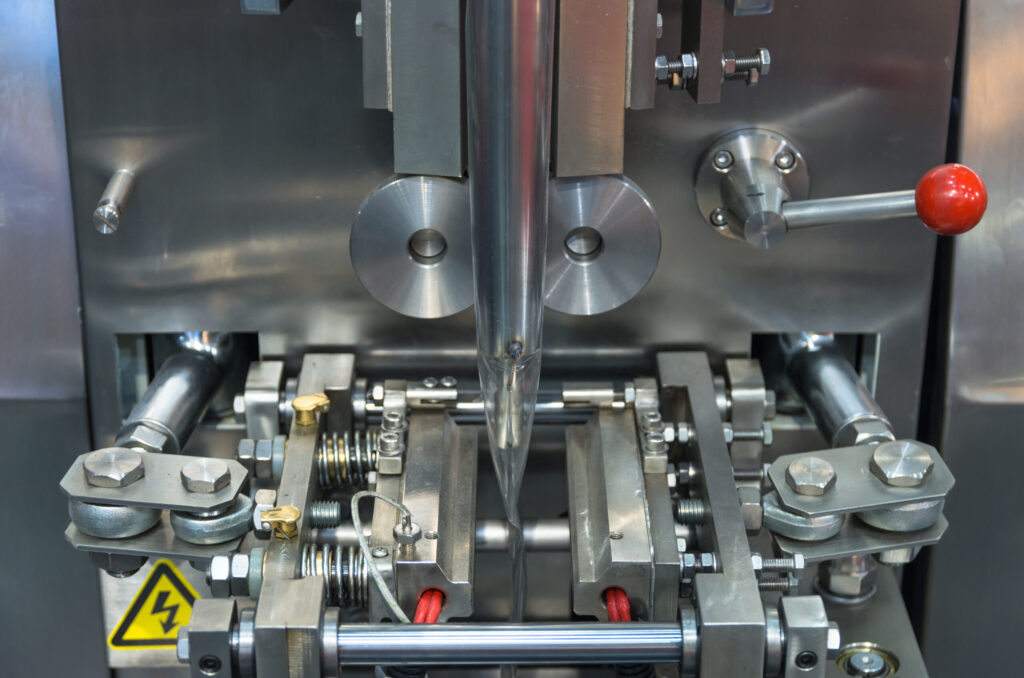

Before investing in freezers, chillers, compressors, evaporators, stainless tanks, or other food and refrigeration equipment, it is critical to define the scope of your operational needs clearly. This involves assessing the size, scale, and nature of your projects. Analyze the materials you’ll be working with, the volume of production you aim to achieve, and the precision required in your processes. The uniqueness of each industrial operation demands a tailored approach to equipment selection.

Once you have identified your requirements, research the options available in the market that best meet these needs. Not all equipment is made equal; some may offer more power, while others might provide better accuracy. Be sure to consider current and prospective projects to ensure that the selected equipment will serve you both in the present and the future.

Another aspect to consider is the space available in your facility. Larger, more complex machinery may offer extensive capabilities, but it requires significantly more room for operation and maintenance. Utility requirements such as power and water supply also play a pivotal role in determining the right equipment for your setting.

Additionally, integrating new equipment into your existing workflow should be seamless. The machinery should complement and enhance your production line, not cause bottlenecks due to compatibility issues with other pre-installed equipment or software systems. Training employees to operate new machinery effectively is an integral part of this process.

Evaluating the Equipment’s Performance and Reliability

The performance of industrial equipment directly impacts productivity levels and, consequently, the bottom line. Researching and comparing different models and their performance statistics is paramount. Consider energy consumption rates, output speeds, and the equipment’s track record in similar industries. The performance should align well with your operational capacity and business goals.

Reliability cannot be compromised when it comes to industrial machinery. It’s not just about the machine functioning correctly but also its durability and longevity. Investing in equipment that frequently breaks down can lead to significant losses due to downtime and repair costs. Look for equipment with robust construction, high-quality materials, and positive reviews regarding reliability and lifespan.

When considering equipment, it’s also essential to think about how it will handle peak loads and whether it can operate continuously without compromise. Overloading machinery leads to premature wear and tear, so selecting equipment that can comfortably handle your projected peak demands is crucial for long-term reliability.

Considering the Total Cost of Ownership

While the initial purchase price of industrial equipment is a significant factor, the total cost of ownership (TCO) provides a more accurate picture of the long-term financial implications. TCO will impact your business budget and includes maintenance expenses, operational costs, energy consumption, and the costs involved in training employees to use the equipment effectively.

It’s beneficial to invest in energy-efficient machinery that can help reduce energy bills and align with sustainability goals. The return on investment through savings on utility bills and possible tax incentives can be significant over time.

Lastly, consider the availability and cost of replacement parts. It’s inevitable that over the lifespan of the equipment, certain parts will need to be replaced. Ensuring that these parts are readily available and affordable is key to maintaining the machinery without interruption to your business processes.

Overall, the selection of industrial equipment is a strategic decision that should be approached with thorough research and a clear understanding of the total cost and benefits. Selecting the right industrial equipment requires careful consideration of your business needs, the quality and reliability of the equipment, and cost-effectiveness. By considering all of the factors carefully, you can make an informed decision that aligns with your business goals and ensures long-term success.